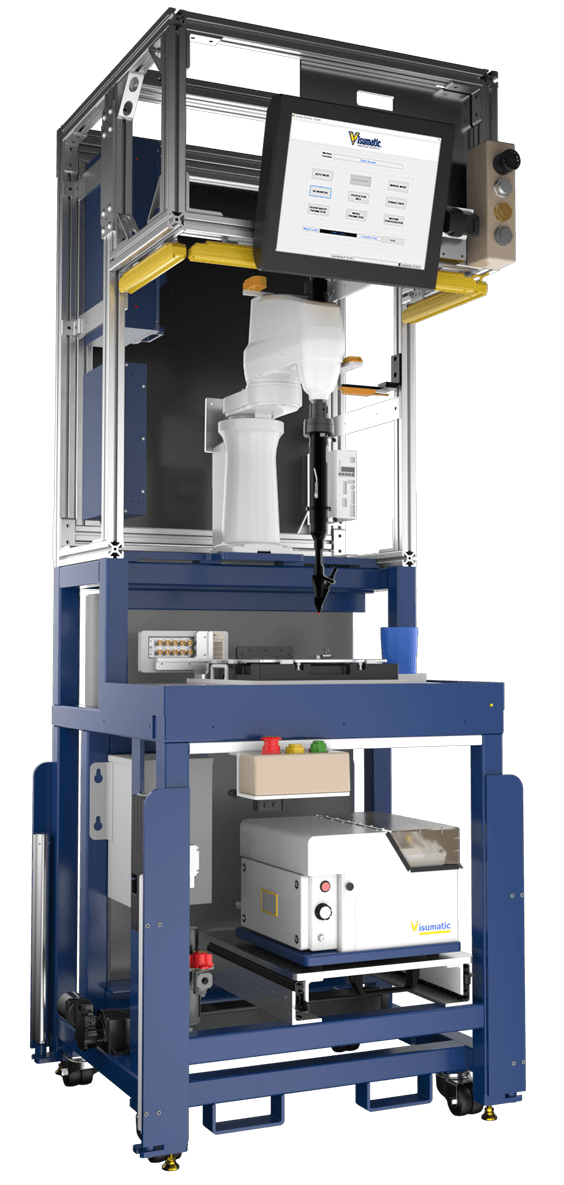

SCARA 4-Axis Robotic Screwdriver

Application: Turnkey robotic screwdriver assembly machine for lightning-fast error-free production.

The state of the art Viper robotic screwdriver assembly machine is the fastest screw installer available. A fully programmable feeding and driving system, it is designed to be lean and extremely flexible, incorporating a super-fast SCARA 4-axis robot.

Visumatic’s robotic screwdriving platform can handle multiple product assemblies with a variety of pre-programmed quality control combinations. This machine is only 30 inches square and has an ergonomic on-the-fly 11 inch height adjustment. Configuration choices include HMI, robot, electrical, pneumatic and paint schemes to suit.

The Visumatic Advant-edge

Flexible work cell for factories where precision assembly is prime and floor space is valuable.

A variety of robotic screwdriver options include sensorized part fixturing, biometric security, and pre-loaded programming for teaching future parts. This modular fastening platform can be retooled, lowering cost of ownership.

Ready to work with these great features:

- 4-Axis SCARA robot

- Built in quality control with NST traceable axis

- 7,000+ cubic inch working envelope

- Feed to Tip robotic screwdriver nosepiece assembly

- Visumatic Model 94 automatic feeder system

- DC torque/angle control and rundown monitoring tools

- Scalable pre-programmed controls, including robot vision

- Adaptable graphical operator interface panel

A quality assured robotic screwdriver platform backed by the greatest fastening capability worldwide.

CASE STUDY

Multiple Robots Deliver Iron-Clad Quality Control without Raising Headcount

A Tier 1 automotive interior trim manufacturer was tooling up for a new model year. The final assembly plant wanted the parts delivered in sets as they were to be vehicle installed on the line.